Expert Industrial Drone Mapping & Inspection Services

IMACHINE's Drone & Robotics Platform with in-house fleet, unifies mobile ground and aerial robotics operations in harsh environments and has proven reliable in the field for piloted or autonomous Beyond Visual Line of Site (BVLOS) missions.

Combining hard science with safety, skill and an element of art - our clients have been very impressed with the high quality engineering deliverables we provide.

Plant & Asset 3D Modelling

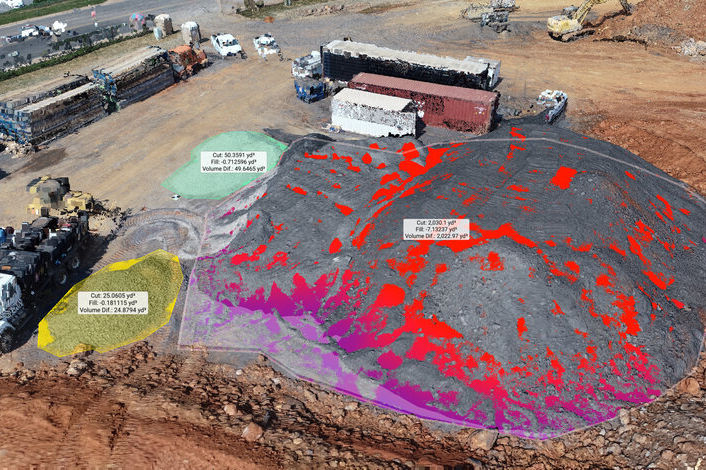

Advanced 2D & 3D Site Mapping

Aerial Thermal Imaging, Condition Analysis - Plant and Equipment Inspections

IMACHINE are pioneers of safely flying drones and controlling robotic inspection rovers in and near Hazardous Areas in the energy, oil & Gas and waste industries and at mission critical sites such as mining and quarry operations. Our team of researchers, engineers, drone pilots and technicians have a wealth of hands on engineering and application experience in the application of drones and robotic rovers for industrial facility inspection, condition analysis, 2D mapping and 3D modelling.

With decades of combined years in the industry, we understand the Australian Standards, rules a regulations, especially Hazardous Areas, where we have developed a unique solution for this application. We have invested in an array of fit for purpose drones and camera/inspection payloads, for 2D mapping, 3D modelling, equipment inspection, gas/leak detection and thermography.

Flying drones and operating robotic inspection rovers in Hazardous Areas (Explosive Atmospheres) can be high risk, where you need a partner who can operate safely to minimise the risk of ignition. iMACHINE will work with your team to minimise the risk of drone and robotic rover use in or near to the Hazardous Area. All work is conducted under risk assessment, utilising gas detectors or other equipment for dust environments and hot work permits, where flight paths exclude the HA Zones and missions are planned to ensure safe returns to landing, avoiding unnecessary risks to both personnel and plant.

iMACHINE's team can provide high end deliverables with our fleet of drones, rovers and other equipment including:

-

Aerial 2D mapping and orthomosiacs (non-survey or survey grade - with 3rd party surveyor);

-

Plant Layouts or updates to layouts, using the RTK corrected Aerial maps;

-

3D modelling and plant digital clone (3D twin) with photogrammetry or fusion options;

-

3D Isometric Views, for Engineering Drawings, such as plant layouts, HA Classifications, Process Modelling etc.

-

3D modelling with LiDAR and photogrammetry or fusion options, for engineering CAD grade models;

-

High resolution and high zoom (200x / 48MP) inspection photos;

-

High resolution thermal imaging and reports;

-

AS/NZS 60079 series - EEHA (Electrical Equipment for Hazardous Areas) Inspections and Audits utilising drones for inspection or difficult to access equipment;

-

Electrical, Mechanical and Process Equipment condition analysis and reporting, with a combination of wireless sensing data, drone data and manually collected data.

-

Asset management and compliance assistance.

We have a strong understanding of Australian Standards, rules and regulations and can also offer complete compliance services to assist in the process of compliance auditing, design reviews and specific compliance certifications for electronic hardware, wireless systems, RF devices, battery energy storage, solar/wind energy, intrinsically safe devices, EEHA and communication products.

EXAMPLE DRONE 3D MODELLING PROJECT IN A HAZARDOUS AREA

HERE IS THE ORIGINAL PLANT 3D MODEL FROM GOOGLE SATELLITE IMAGERY:

HERE IS THE MODEL OF THE PLANT AS A "DIGITAL CLONE" USING ADVANCED 3D PHOTOGRAMMETRY SOFTWARE:

Note that this is the raw model with our lower specification drone. Higher resolution and better results could be achieved through the use of our higher end drones and also longer drone flight times, further post processing and cleaning up of the 3D model, depending upon the project requirements and budget.

Contact us today to discuss your drone mapping, 3D modelling, plant inspection and compliance needs.

To contact us regarding your Drone Mapping, 3D modelling, Inspection and Condition Monitoring Engineering solutions, please fill in the contact form below and we will respond: